Top 5 Mistakes in 5 Whys Analysis

When troubleshooting recurring issues, the 5 Whys method can help identify root causes rather than just treating symptoms. However, many teams misuse this technique, leading to repeated failures and wasted resources. Here are the top five mistakes to avoid:

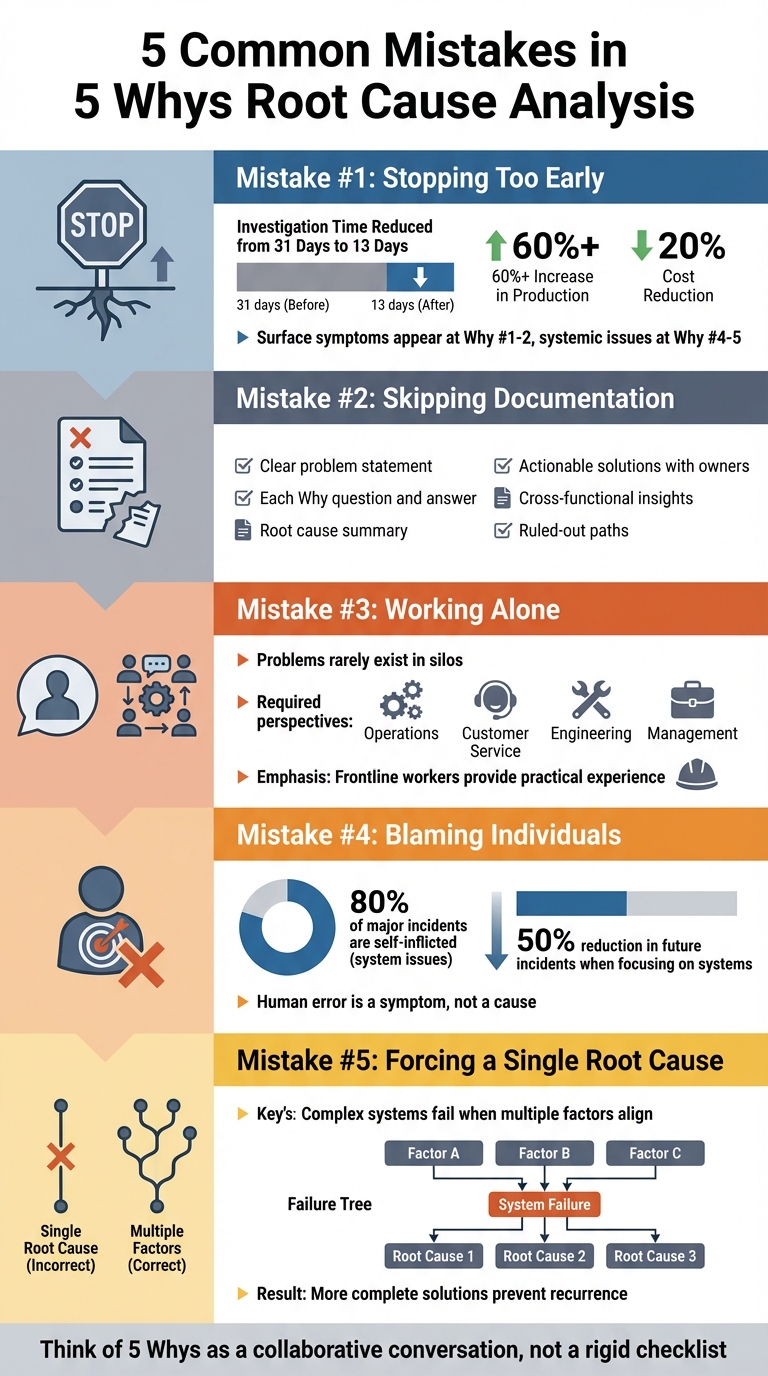

- Stopping too early: Ending the process after one or two "Whys" often uncovers only surface-level symptoms, not the real cause.

- Skipping documentation: Failing to record findings leads to repeated efforts and missed opportunities for learning from past issues.

- Working alone: A lack of diverse input limits perspectives and increases the chance of missing critical factors.

- Blaming individuals: Focusing on "human error" instead of systemic flaws discourages learning and improvement.

- Forcing a single root cause: Complex problems often have multiple contributing factors; oversimplifying leads to incomplete solutions.

5 Common Mistakes in 5 Whys Root Cause Analysis

What’s WRONG with the 5 WHYS | Humanizing Work Show | Mailbag

sbb-itb-f9e5962

1. Stopping Too Early

One of the biggest pitfalls in root cause analysis is stopping after just one or two "Whys." This approach often uncovers surface-level symptoms rather than the deeper, underlying cause. The result? Temporary fixes that don’t address the real problem.

Take this example: a server crashes, and the team identifies overload as the issue. If the solution stops at adding resources, the real problem – perhaps a marketing campaign launched without IT’s involvement due to a missing communication protocol – remains unresolved. Overload is just a symptom; the lack of a proper communication process is the actual root cause.

Stopping too soon can lead to a frustrating cycle of "firefighting", which wastes time, money, and resources. On the other hand, organizations that fully commit to root cause analysis have seen impressive results. For instance, some reduced investigation times from 31 days to just 13. Others, by embedding lean problem-solving methods, reported over 60% increases in production and 20% cost reductions.

Why does this happen? Early answers often blame individual mistakes or technical glitches. But the deeper insights – those that reveal systemic issues like broken processes, insufficient training, or flawed policies – usually appear around the fourth or fifth "Why". Here’s a simple test: if fixing the identified issue doesn’t guarantee the problem won’t happen again, you need to keep asking "Why".

Next, we’ll look at how skipping documentation can weaken your analysis.

2. Skipping Documentation

Stopping short of thorough documentation can seriously undermine your root cause analysis. If you skip recording your 5 Whys process, you lose a vital piece of organizational memory. When a similar issue arises, you’ll have to start from scratch – wasting valuable time. By documenting your analysis systematically, you can avoid revisiting the same problems over and over.

Detailed documentation does more than just preserve history – it helps identify patterns and process gaps. When teams consistently record their findings, they’re better equipped to spot recurring issues that might be missed during isolated troubleshooting efforts.

Accurate documentation also improves future problem-solving. Here’s what you should capture during your analysis:

- A clear problem statement: Include details about what went wrong, when it happened, where it occurred, and its impact.

- The 5 Whys process: Record each "Why" question alongside its answer to maintain the logical flow.

- Root cause summary: Provide a concise explanation of the final root cause.

- Actionable solutions: Outline a plan with assigned owners and deadlines for resolving the issue.

- Cross-functional insights: Document input from team members across departments to add context for future investigations.

- Explored but ruled-out paths: Note any "dead ends" to show the depth of the investigation.

"The 5 Whys method helps you dig past surface symptoms to discover the actual process breakdowns, communication gaps, or system failures you can fix permanently." – Chaviva Gordon-Bennett, Content Strategist, Monday.com

To ensure nothing is missed, assign someone to act as a scribe. They can record the discussion in real time, whether on a whiteboard or using a shared digital tool. Afterward, perform a "reverse test" by reading the chain backward with "therefore" to confirm the logic. Finally, formalize the analysis in your project management system to keep corrective actions on track.

3. Working Alone or Without Diverse Input

Conducting a 5 Whys analysis on your own can lead to blind spots. Personal biases and a limited perspective often make it hard to pinpoint the true root cause. If the issue falls outside your area of expertise, there’s a risk of applying quick fixes that only address symptoms. While documenting each step is essential, gathering input from multiple perspectives is just as critical when digging into root causes.

Collaborating with others enriches the analysis process. Problems rarely exist in silos. For example, an IT issue might actually result from a gap in the sales process, or a deployment failure could trace back to unclear communication between teams. Involving people from different departments – like operations, customer service, engineering, and management – helps paint a more complete picture of how the problem affects the organization.

"5 whys is a team effort. Everyone involved in the incident should be involved in its postmortem. People with hands-on experience need to be in the room." – Atlassian

Input from frontline workers is especially valuable. Their practical experience ensures the analysis remains grounded in actual operations rather than abstract theories.

To make the process even more effective, assemble a cross-functional team that includes individuals from various roles and levels of seniority. A neutral facilitator can help guide the discussion and keep it productive. This collaborative method not only improves the quality of insights but also fosters shared responsibility for the solution, making it more likely to succeed.

4. Blaming Individuals Instead of Systems

Focusing on individual mistakes instead of system flaws disrupts the learning process. When leadership asks, "Who messed up?" rather than "What went wrong in the system?", it discourages team members from sharing the insights needed to improve processes. This turns the discussion into a blame game instead of a constructive investigation into the real issues.

The truth is, human error is rarely the root cause. It’s a symptom of deeper, systemic problems. When someone makes a mistake, the follow-up question should always be: "What in the system allowed this to happen?". For instance, outdated runbooks, missing documentation, or pressure to bypass safeguards often pave the way for errors. These are the areas that need attention.

The numbers back this up: about 80% of major incidents are self-inflicted, often due to poorly managed deployments or configuration changes. Organizations that focus on fixing systemic issues instead of assigning blame can cut future incident rates by 50%. If the same mistake happens with different people at different times, it’s a clear sign of a broken process, not individual incompetence.

"Human error is a symptom, never the cause, of deeper trouble in the system." – Dave Zwieback, former Head of Engineering, Next Big Sound

Take Amazon‘s OpenSearch Serverless outage in 2026 as an example. An 11-hour availability issue initially pointed to the CortexOperator reducing ingesters incorrectly. Instead of blaming the deployment team, the analysis uncovered that the code couldn’t handle new Kubernetes label formats introduced in version 1.17. The solution? Adding label format detection logic and improving upgrade testing procedures – system-level changes, not finger-pointing.

Avoid using terms like "human error", "carelessness", or "negligence" in your documentation. If your analysis ends with advice like "be more careful next time", you haven’t truly addressed the root cause. Instead, rely on concrete facts from maintenance logs and operational data, steering clear of assumptions about individual performance.

Up next, we’ll explore why forcing a single root cause onto complex problems can lead to oversimplified and ineffective solutions.

5. Forcing a Single Root Cause on Complex Problems

Cloud failures are rarely straightforward. Yet, teams often approach the 5 Whys as if there’s a single root cause that explains everything. The truth is, failures in complex systems happen because multiple factors align simultaneously, not because of one isolated issue.

It’s easy to see why the idea of pinpointing one root cause is tempting – it offers closure and a clear plan of action. But as Sidney Dekker, an author and professor, explains:

"Cause is something we construct, not find. And how we construct causes depends on the accident model that we believe in".

This mindset often leads teams to stop their analysis too soon, settling on the first convenient answer or halting when they run out of data. While declaring a singular cause might feel satisfying, it often ignores other critical contributing factors. These overlooked elements remain in the system, waiting to interact with new triggers in the future. Nancy Leveson, author of Engineering a Safer World, highlights this complexity:

"The selection of an initiating event is arbitrary and previous events could always be added".

Instead of forcing a linear explanation, let your analysis branch out. When you encounter a "Why" with multiple answers, explore all of them. Think of your investigation as a tree with multiple roots, rather than a single chain. Asking "How did this happen?" allows you to uncover the conditions and interconnections that led to the failure. Before wrapping up, run a reverse test: if you fixed the identified "root cause", would it fully prevent the problem from occurring again? If not, your analysis isn’t complete.

Organizations that embrace this broader approach see tangible benefits. For example, companies that adopted thorough root cause analysis – accounting for multiple factors – reduced their investigation time from 31 days to 13 days, while boosting production by over 60% and cutting costs by 20%. The takeaway? Success and failure are products of complex systems, and no single fix can address every issue.

Conclusion

The five mistakes discussed – quitting the process too soon, skipping proper documentation, tackling problems solo, blaming individuals, and insisting on a single root cause – often result from prioritizing speed over thorough analysis. When you rush through the 5 Whys, you risk addressing only surface symptoms while leaving deeper systemic problems untouched.

Avoiding these missteps creates opportunities for true system improvements. A well-executed root cause analysis, backed by evidence, not only resolves issues more effectively but also reduces repeat incidents and optimizes resource allocation.

Think of the 5 Whys as a collaborative conversation rather than a rigid checklist. As Sumit Shinde wisely notes:

"If your process allows one person’s mistake to cause a significant problem, your process is inadequate".

Every analysis should focus on refining processes, not assigning blame. Use data from logs and monitoring tools to validate your findings, and involve team members who work directly with your systems. These steps ensure meaningful, lasting improvements in incident response.

You might also consider tools like Fishbone diagrams or Fault Tree Analysis to complement the 5 Whys approach. The ultimate goal isn’t to stick to a specific framework – it’s to fully understand what went wrong so you can stop it from happening again.

If you’re an engineering-aware founder looking for reliable infrastructure without becoming an infrastructure expert yourself, TechVZero can help. With experience managing systems at a scale of 99,000+ nodes and saving clients $333,000 in a single month while mitigating a DDoS attack, we bring insights that cut through the noise of vendor marketing to deliver what truly works.

FAQs

How do I know when to stop asking “Why?”

When conducting a 5 Whys analysis, stop asking "Why?" once you’ve pinpointed a root cause that is both actionable and sustainable – and doesn’t mask deeper issues. Be cautious not to stop too early, as this might only tackle surface-level symptoms. On the flip side, asking "Why?" for too long can lead to unnecessary complications. A solid stopping point usually highlights a process or system flaw rather than placing blame on individuals, ensuring the issue is specific and can be effectively addressed.

What should I document during a 5 Whys analysis?

To effectively address an issue, it’s essential to document the problem thoroughly, identify the causes at every step, and determine whether each cause is the root cause or if it demands further investigation. This method ensures a logical progression of reasoning, creating a clear path to uncover the underlying issue.

By breaking the problem into smaller parts and questioning each step, you can pinpoint the exact cause. For instance, if a machine malfunctions, the initial problem might seem mechanical. However, by digging deeper, you might find the root cause is poor maintenance or a design flaw. This process not only clarifies the issue but also prevents future recurrences.

How do I handle multiple root causes in 5 Whys?

When tackling problems with multiple root causes using the 5 Whys process, it’s important to understand that issues often stem from more than one factor. To address this, you can either conduct separate 5 Whys analyses for each identified cause or extend your questioning to cover all contributing elements. For more intricate problems, consider pairing the 5 Whys with tools like Ishikawa diagrams (also known as fishbone diagrams). This combined approach helps you systematically pinpoint and address all root causes, reducing the likelihood of the issue happening again.